ABOUT US OVERVIEW

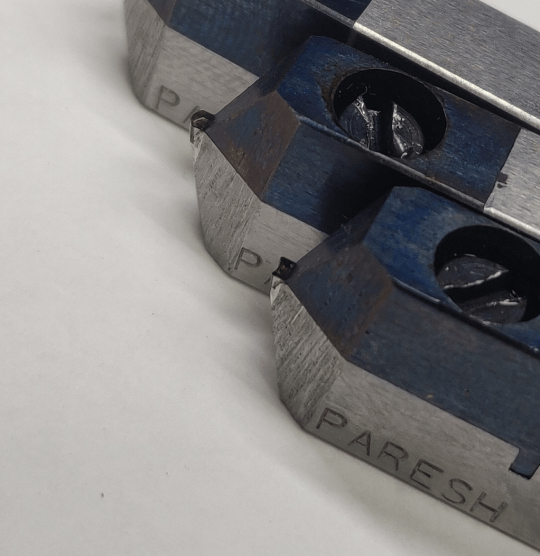

Paresh tools is a manufacturing company of Posalux type diamond tools since 1982. Our Company is Specially concentrating on Quality and accuracy to get good shine and good effect after cutting on jewellery. Tools are set in the shank with special techniques With more than 35 years of experience, Paresh tools manufactures the finest diamond tools to suit all your needs. Exporter and Manufacturer of Jewelley making tools (Posalux Diamond tools / CNC tools / Hammer tools / Flywheel tools / PCD tools / Lathe tools for Precision Engineering and Jewellery engraving.

We select a special industrial diamond with maximum hardness. We set diamond with modern techniques to avoid shaking and vibration. We have skilled artisans, also we use modern technology and upgrade our self for the betterment. Each tool is tested and passed through a microscope and testing machine.

Paresh tools is a manufacturing company of Posalux type diamond tools since 1982. Our Company is Specially concentrating on Quality and accuracy to get good shine and good effect after cutting on jewellery. Tools are set in the shank with special techniques With more than 35 years of experience, Paresh tools manufactures the finest diamond tools to suit all your needs. Exporter and Manufacturer of Jewelley making tools (Posalux Diamond tools / CNC tools / Hammer tools / Flywheel tools / PCD tools / Lathe tools for Precision Engineering and Jewellery engraving.

We select a special industrial diamond with maximum hardness. We set diamond with modern techniques to avoid shaking and vibration. We have skilled artisans, also we use modern technology and upgrade our self for the betterment. Each tool is tested and passed through a microscope and testing machine.

The shining and soft cutting is the main prime concern areas of Paresh TOOLS. We maintain a high quality of Diamond tools for international as well as domestic market. We only manufacture the same quality for all our customers. As quality is where we are more focused and to serve our customers with a good product as well as quality. Our large clientele list of customers around the world has proven the quality of our tools.

HOW WE CONTROL OUR QUALITY

So when you use Paresh tools your satisfaction is guaranteed as regards to durability and perfection. We have a system, that gives our tools the quality and the durability that is needed. QUALITY CONTROL [QC] is emphasized on brazing, turning, planning and many other factors, that helps our tools to be more perfect in high quality. Selected diamond is used as a raw material to give you the value for your money.

So when you use Paresh tools your satisfaction is guaranteed as regards to durability and perfection. We have a system, that gives our tools the quality and the durability that is needed. QUALITY CONTROL [QC] is emphasized on brazing, turning, planning and many other factors, that helps our tools to be more perfect in high quality. Selected diamond is used as a raw material to give you the value for your money.

Our range of tools is high appreciated by the clients in domestic as well as international market due to their exclusive features like precision-engineered, durability, compact design, and low maintenance. We have developed a modern infrastructure, which helps us in meeting the bulk requirements of our clients within the committed time frame. Our team of experts utilizes all machines and equipment installed at our infrastructure to manufacture a precision range of tools, which conform to industrial quality norms. We select a special industrial diamond with maximum hardness. We set diamond with modern techniques to avoid shaking and vibration. We have skilled artisans , also we use modern technology and upgrade our self for the betterment. Each tool is tested and passed through a microscope and testing machine.

HOW TO PLACE AN ORDER

Diamond size should be in millimeter degree of diamond Fancy shape ; convex , concave lining, for a special type of tools provide picture or drawing.